October 6, 2025

What Drives Electric Power Flow in Diesel-Electric Locomotive Engines?

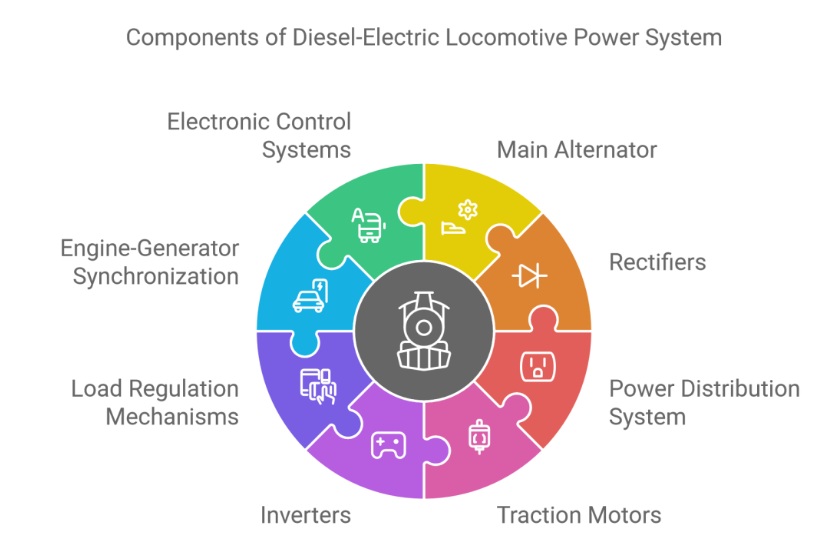

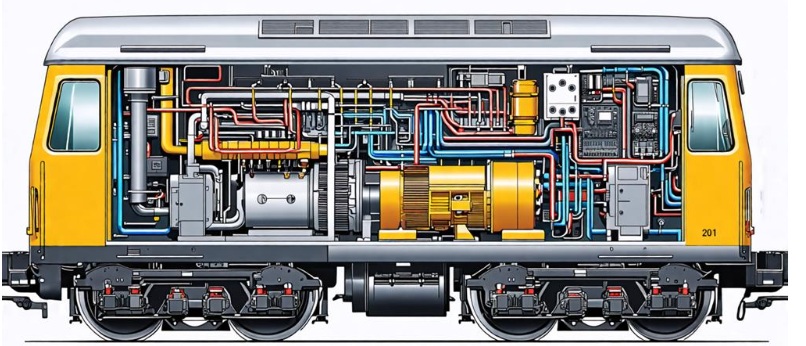

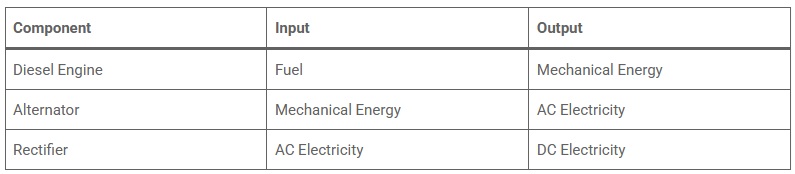

In diesel-electric locomotives, electric power flow is driven by a complex system of components. The main alternator converts the diesel engine’s mechanical energy into electrical power. This AC electricity is then rectified to DC and distributed through a sophisticated power distribution system. Traction motors, controlled by inverters, convert this electricity back into mechanical force for propulsion. Load regulation mechanisms continuously adjust power output to match demand, while engine-generator synchronization guarantees peak efficiency. The entire process is managed by advanced electronic control systems that monitor and fine-tune operations in real-time. Understanding these interconnected systems reveals the intricate engineering behind locomotive power.

Key Takeaways

The diesel engine acts as the prime mover, generating mechanical energy to power the main alternator.

The main alternator converts mechanical energy into electrical energy, producing AC power for the locomotive.

Rectifiers transform AC to DC, while inverters convert DC back to AC for efficient power distribution.

Traction motors receive electrical power and convert it into mechanical force, driving the locomotive’s wheels.

Advanced electronic control systems regulate power flow, optimizing efficiency and performance across varying operational demands.

The MainAlternator’s Role

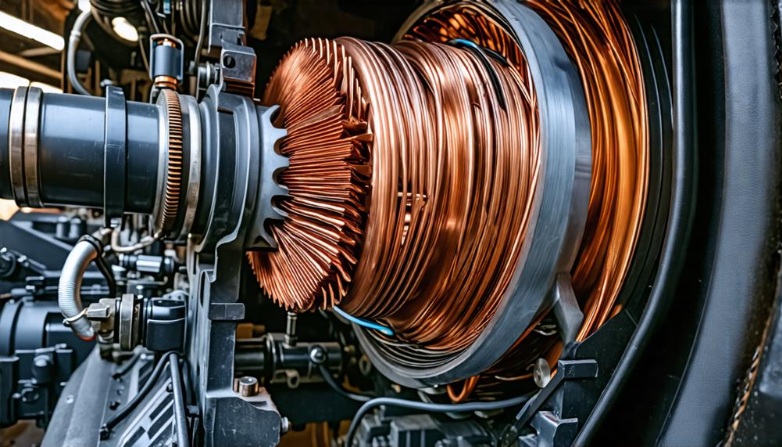

At the heart of a diesel-electric locomotive’s power system, you’ll find the main alternator. This essential component serves as the primary interface between the diesel engine’s mechanical energy and the electrical power required to drive the locomotive’s traction motors. As the diesel engine operates, it spins the main alternator at high speeds, typically up to 1,000 RPM, to generate alternating current (AC) electricity efficiently.

The main alternator’s role extends beyond mere energy conversion. It’s a key element in the locomotive’s power transmission system, greatly enhancing mechanical efficiency compared to traditional direct-drive systems. By converting mechanical energy to electrical energy, you’re able to achieve greater flexibility and control over power distribution throughout the locomotive.

You’ll notice that the main alternator’s output isn’t static. In modern systems, it can be dynamically adjusted to meet varying load demands. This adaptability allows for optimized performance across different operational conditions, ensuring that you’re always getting the most efficient power output for your current needs.

The AC electricity produced by the main alternator doesn’t directly power the traction motors. Instead, it’s first rectified to direct current (DC) by a rectifier. This conversion process is essential for supplying the appropriate type of electrical energy to the traction motors, which are responsible for propelling the locomotive forward. By understanding the main alternator’s central role, you’ll gain insight into the sophisticated power flow that drives modern diesel-electric locomotives.

Traction Motorsand Propulsion

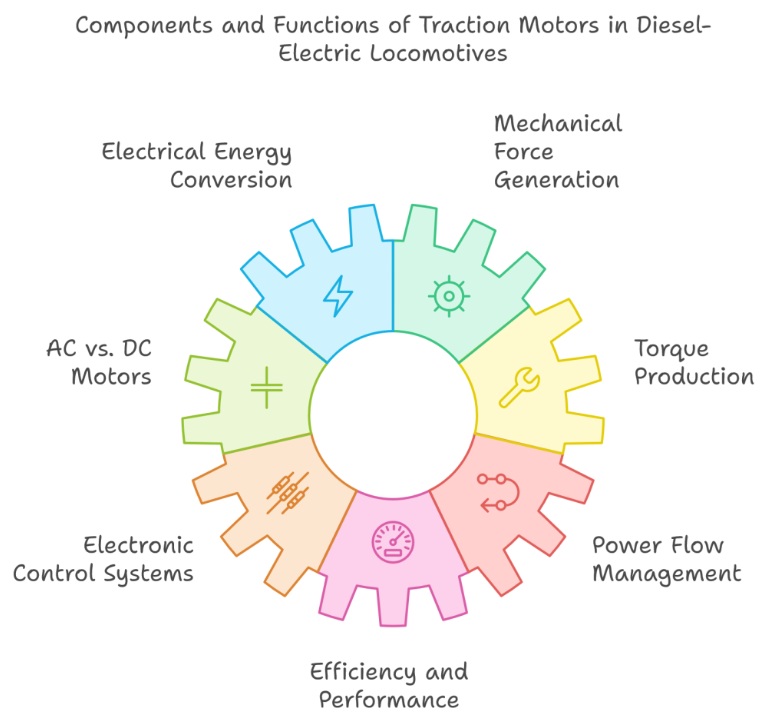

Invariably, traction motors serve as the locomotive’s primary means of propulsion, converting electrical energy into mechanical force. In diesel-electric locomotives, these motors are directly connected to the axles, guaranteeing efficient power distribution and enhanced traction. You’ll find that modern designs often utilize AC traction motors due to their superior efficiency and power output compared to their DC counterparts.

The traction motors in diesel-electric locomotives are capable of producing immense torque, often exceeding 60,000 lb-ft. This tremendous force is vital for initiating movement in heavy freight trains and maintaining speed on challenging inclines. As you operate the locomotive, sophisticated electronic control systems manage the power flow to these motors, fine-tuning performance based on real-time operational demands and conditions.

To visualize the impact of traction motors on a diesel-electric locomotive, consider:

The locomotive’s wheels gripping the rails as the traction motors engage, overcoming inertia

Powerful surges of electric current flowing through the motors as the train accelerates

The rhythmic hum of the motors as they maintain a steady speed on long stretches of track

The efficiency of traction motors in converting electrical energy to mechanical energy is paramount in diesel-electric locomotives. You’ll notice that the control systems continuously adjust motor current to match the specific requirements of your journey, whether you’re hauling freight across flat terrain or steering through steep mountain passes. This precise regulation of electric power guarantees peak performance and fuel efficiency throughout your locomotive’s operation.

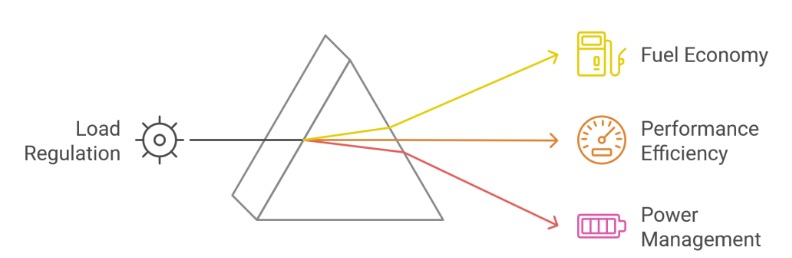

Load RegulationMechanisms

Load regulation mechanisms form the backbone of efficient power distribution in diesel-electric locomotives. These systems continuously monitor and adjust the generator’s output based on engine load demands, guaranteeing peak performance across various operating conditions. You’ll find controllers that modulate the generator’s field strength, responding to real-time data from speed sensors and torque measurements.

As you operate a diesel-electric locomotive, the load regulation system works tirelessly to:

Prevent wheel slip by fine-tuning power delivery to traction motors

Maximize fuel consumption by matching generator output to actual power needs

Reduce wear on mechanical components through precise power management

Advanced electronic control systems enhance load regulation efficiency. They employ sophisticated algorithms that can predict load changes, allowing for preemptive adjustments to generator output. This predictive capability improves the locomotive’s responsiveness and overall performance.

You’ll notice that effective load regulation contributes considerably to the locomotive’s fuel economy. By precisely controlling power output, the system guarantees that you’re not wasting energy or overworking the engine unnecessarily. This maximization extends to traction motor performance, where load regulation helps maintain the ideal balance between power delivery and wheel adhesion.

In modern diesel-electric locomotives, load regulation mechanisms integrate seamlessly with other subsystems. They work in concert with rectifiers and inverters to manage the flow of power from AC to DC and back, as needed by various onboard systems. This intricate dance of power management guarantees that your locomotive operates at peak efficiency, regardless of the demands placed upon it.

Power DistributionSystem

The power distribution system in diesel-electric locomotives forms the essential link between the main alternator and the traction motors. It’s responsible for efficiently channeling electrical energy from the alternator to the various components that require power, primarily the traction motors that drive the wheels.

In this system, the alternator generates AC electricity, which is then rectified to DC for more effective distribution. You’ll find that this conversion process allows for better control and management of the electrical power flow throughout the locomotive. The DC power is then directed to the traction motors, typically mounted on each axle, where it’s converted back into mechanical energy to propel the locomotive forward.

Advanced electronic control systems play a significant role in the power distribution process. They constantly monitor and adjust the flow of electricity to enhance performance and respond to changing operational demands. These systems guarantee that each component receives the appropriate amount of power at the right time, maximizing efficiency and reducing waste.

You’ll also encounter various safety components within the power distribution system, such as circuit breakers and protective devices. These elements safeguard the electrical network from overloads and short circuits, maintaining the integrity of the system during operation.

The power distribution system’s design allows for flexibility in meeting diverse operational requirements. It can adapt to varying loads, speeds, and track conditions, guaranteeing that your locomotive maintains peak performance across a range of scenarios. This adaptability is key to the overall efficiency and reliability of diesel-electric locomotives in modern rail operations.

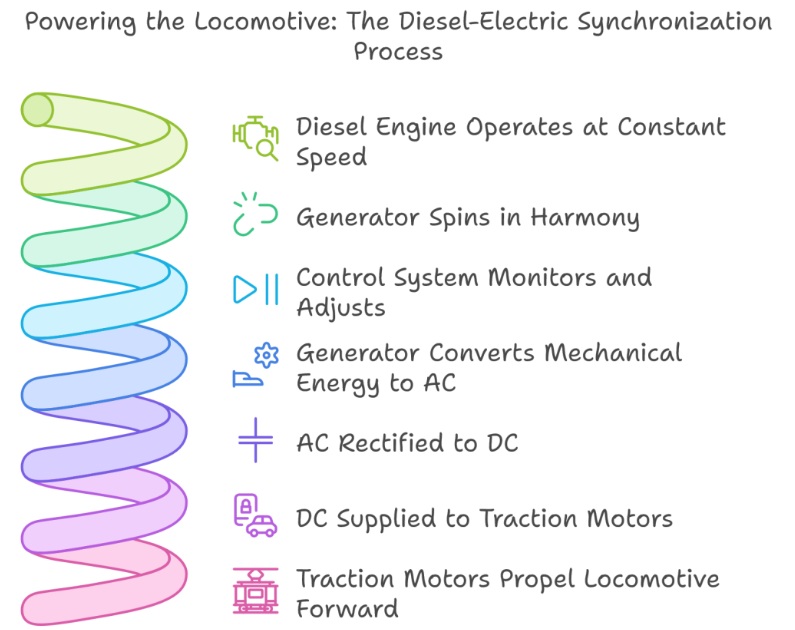

Engine-Generator Synchronization

At the heart of a diesel-electric locomotive’s power generation system lies the vital process of engine-generator synchronization. This intricate dance between the diesel engine and the generator guarantees peak power production for the locomotive’s traction motors.

You’ll find that the diesel engine operates at a constant speed, acting as the prime mover in this system. It’s directly coupled to the generator, which must match the engine’s speed and torque to produce electricity efficiently. The control system plays a significant role in managing this synchronization, continuously monitoring and adjusting the generator’s output based on real-time operational conditions.

As you explore deeper into the system, you’ll notice that the generator converts mechanical energy from the diesel engine into AC electricity. This power is then rectified to DC before being supplied to the traction motors. The control system’s ability to adjust the load on the generator is key to meeting the varying demands of these motors during operation.

To visualize this process, imagine:

A massive diesel engine roaring at a steady rhythm

A generator spinning in perfect harmony with the engine

Traction motors pulsing with electricity, propelling the locomotive forward

The synchronization between engine and generator is not just about matching speeds; it’s about enhancing power generation efficiency. You’ll find that electronic control systems manage this process with precision, making sure that the generator’s output aligns perfectly with the engine’s capabilities and the locomotive’s power needs. This intricate balance is what drives the electric power flow in diesel-electric locomotives, enabling them to operate with remarkable efficiency and power.

Efficiency inElectrical Conversion

Maximizing efficiency in electrical conversion stands as a cornerstone of diesel-electric locomotive design. You’ll find that these locomotives convert mechanical energy from the diesel engine into electrical energy through a generator or alternator. This process achieves highly efficient power generation, setting the stage for ideal performance.

The rotary motion produced by the diesel engine drives the alternator, typically generating alternating current (AC) electricity. This AC is then rectified to direct current (DC) for use in traction motors. These motors, connected to the locomotive’s wheels, convert electrical energy back into mechanical energy, providing efficient power transmission with minimal energy loss.

The electrical conversion process in diesel-electric locomotives allows for exceptional fuel usage efficiency. You can expect these locomotives to move 1 ton of cargo approximately 492 miles per gallon, considerably outperforming traditional steam engines. This impressive efficiency is further enhanced by advanced control systems that optimize electricity flow and manage power distribution based on operational demands.

Frequently AskedQuestions

How Doesa Diesel Locomotive Generate Electricity?

You’ll find that a diesel locomotive generates electricity through a multi-step process. First, it ignites diesel fuel in its engine, creating high-pressure gases that drive pistons. This mechanical energy’s then converted into rotary motion, powering an alternator or generator. The alternator produces AC electricity, which is rectified to DC for improved efficiency. Traction motors use this DC power, converting it back to mechanical energy to drive the locomotive’s wheels. Turbochargers may enhance overall performance.

How DoElectric Trains Get Their Electricity?

You’d be amazed at the thunderous power coursing through electric trains! They get their electricity from various sources. Some draw power from overhead wires called catenaries, using pantographs to maintain contact. Others utilize a third rail system, collecting electricity through a shoe that slides along the rail. In diesel-electric locomotives, you’ll find onboard generators driven by diesel engines, producing electricity to power the traction motors. Each system’s designed for specific operational needs and infrastructure constraints.

What Isthe Power Output of a Diesel Electric Locomotive?

You’ll find that a typical diesel-electric locomotive generates around 3,200 horsepower from its diesel engine. This power’s converted to electrical energy via an alternator, driving the locomotive’s traction motors. Some advanced models can reach 4,000 horsepower or more. The system’s efficiency allows for variable power output based on operational demands. With turbocharging and electric traction control, you’ll see enhanced performance, especially in challenging conditions. Power output can be adjusted for ideal fuel usage during operation.

What Isthe Driving Mechanism of Electric Locomotive?

You’d think locomotives run on the power of your morning coffee, but alas, it’s a bit more complex. The driving mechanism of electric locomotives is primarily traction motors. These motors convert electrical energy into mechanical power, propelling the locomotive forward. You’ll find they’re fed by an alternator, which is driven by a diesel engine. The system’s efficiency is optimized through sophisticated control systems that regulate power distribution based on operational demands.

How toRebuild EMD Locomotive Power Assembly

Rebuilding an EMD locomotive power assembly requires systematic disassembly, thorough inspection, and precise reassembly. You’ll need to follow strict torque specifications while replacing worn pistons, rings, liners, and valves. Always document pre-rebuild conditions, clean components with approved methods, and verify measurements against OEM tolerances. Use proper tooling for connecting rod installation and cylinder head mounting. Load testing confirms proper operation and prevents premature failures. The following steps will guide your complete rebuild process.

Key Takeaways

Inspect power assemblies for wear patterns, cracks, and damage before disassembly, documenting all failure points with boreoscopic evaluation.

Disassemble components systematically, backing off injector rocker arm nuts and extracting rocker shafts while noting spring washer orientations.

Clean components using ultrasonic methods for precision parts and high-pressure washing for external surfaces, ensuring all oil passages are debris-free.

Reassemble in proper sequence, securing liners with crab nuts torqued to 200 ft-lbs and using ring compressors during piston insertion.

Test rebuilt assemblies by verifying clearances, conducting compression and blow-by tests, and performing load testing according to APTA standards.

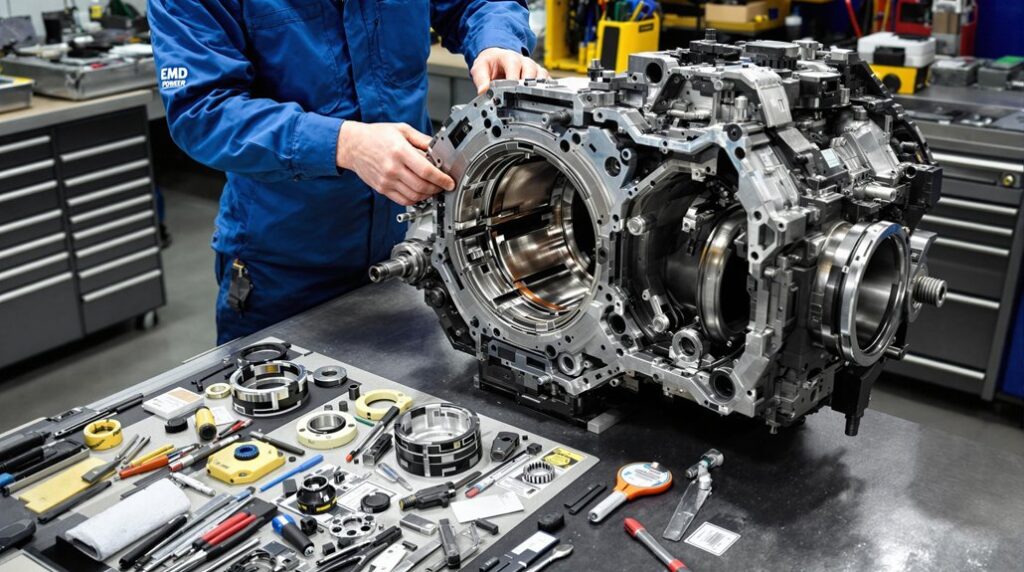

Essential EMDPower Assembly Components

Mastery of EMD locomotive rebuilds begins with understanding its power assembly components. The cylinder head forms the foundation with its valves, springs, and combustion chambers, featuring radial flow designs that enhance airflow in marine applications. The cylinder liner, available in 11-port or standard configurations, includes hardened upper bore surfaces to withstand extreme heat.

Your rebuild requires high-quality pistons made from aluminum or steel, secured with snap rings for proper pin retention. Piston rings are essential for sealing combustion gases and controlling oil consumption, with low-oil variants available to reduce maintenance intervals. Regular maintenance of these components is critical as they operate under high-stress conditions that can lead to premature wear if not properly serviced.

The connecting rod system consists of fork (“master”) and blade (“slave”) rods working in tandem. Fork rods contain bearing inserts for significant wear surfaces, while blade rods require precise alignment during installation. Don’t overlook grade-specific fasteners, which secure important head-to-liner joints and are typically replaced during rebuilds.

Pre-Rebuild InspectionChecklist

You’ll need to conduct a thorough visual assessment of all power assembly components, focusing particularly on cylinder liners for scoring and pistons for crown damage. Material testing requirements include measuring cylinder compression ratios, checking bore diameters against manufacturer specifications, and verifying rocker arm bushing hardness. Document all failure points meticulously, noting wear patterns in valve train components and any abnormal carbon deposits that could indicate combustion issues. Utilize fiber optic endoscopes for detailed internal inspection to identify potential failures before they progress to catastrophic damage.

Component VisualAssessment

Before any rebuild process can begin, a thorough visual assessment of all power assembly components is critical. Using proper visual assessment techniques, you’ll need to inspect the engine block for cracks, damage, and weld integrity, particularly at the lower sump A-frame welds where structural failures commonly occur.

Your inspection tools should include calibrated gauges to verify liner pilot bore alignment with manufacturer specifications. Examine all block joint seals and manifold sleeve seals for deterioration, as these are mandatory replacement items. When examining the head, look for signs of water intrusion which could indicate cracked o-rings in the head gasket. Check the top deck gasket surfaces and verify hood clamp/latch fitness.

For the crankshaft assembly, confirm proper crankcase detector positioning and thoroughly inspect main bearings. Verify that all studs and bolts can achieve the required 200 ft-lbs torque specification.

Material TestingRequirements

After completing the visual assessment phase, you must subject each component to rigorous material testing procedures before proceeding with the rebuild process. Begin with pressure testing to verify cooling system integrity and combustion chamber sealing using specialized pumps that identify deteriorated gaskets or cracked liners.

Perform dimensional measurements with precision micrometers to validate cylinder liner tolerances and piston ring gaps according to AAR M-1003 certification standards. These testing techniques guarantee components fall within EMD specifications.

Finally, conduct metallurgical analysis to evaluate material properties through hardness testing of piston crowns and fatigue crack detection on connecting rods. This testing should include the use of advanced diagnostic tools to ensure accuracy and reliability of all measurements. Apply dye penetrant or magnetic particle inspection to reveal hidden stress points. This thorough testing protocol identifies components that require replacement before assembly begins.

Failure PointDocumentation

Proper documentation of failure points creates the foundation for an effective locomotive power assembly rebuild. Your inspection should thoroughly identify specific failure mechanisms using multiple diagnostic approaches. Begin with boreoscopic evaluation of cylinder walls to detect scoring without full disassembly. Document dropped valves by examining bent stems and peened faces. During your failure analysis, record valve clearance issues that might have caused compression problems or knocking. When examining a cylinder, watch for signs of water intrusion which can cause catastrophic engine damage if left unaddressed.

Test cooling circuits at 15-20 PSI to pinpoint hidden leaks, especially at water passage junctions where o-rings commonly fail. Use ultrasonic leak detection for micro-cracks and magnetic particle testing to identify rod cap fractures. Your documentation methods should categorize all anomalies by component type—valve, cylinder head, cooling system, or connecting rod—allowing you to establish patterns that prevent repeat failures.

Disassembly Processand Best Practices

Disassembly of an EMD locomotive power assembly requires five critical stages executed in precise sequence to maintain component integrity and guarantee workplace safety. Begin by implementing lockout/tagout procedures and donning specialized PPE including heat-resistant gloves and Z87.1-rated welding helmets. You’ll need to position EMD-specific tools within reach and ascertain proper workspace organization with designated areas for components.

Relieve valve train pressure by backing off injector rocker arm lock nuts before disconnecting oil supply lines

Extract rocker shafts with proper support clamps while noting spring washer orientations for reassembly

Position pistons at 120° after TDC for blade rod access or 22.5° for fork rod removal

Secure connecting rods with dedicated clamps to prevent sleeve damage during extraction

These disassembly techniques require methodical execution in a properly ventilated workspace with explosion-proof lighting. The complete power assembly weighs approximately 440 pounds with a fork rod installed, requiring adequate lifting equipment for safe handling. Remember to tag components systematically for efficient cataloging and subsequent reassembly.

Critical ComponentAnalysis and Measurement

When rebuilding an EMD locomotive power assembly, systematic inspection of all critical components is essential for ensuring operational reliability. This includes precise measurement of piston rings, cylinder liners, and valve seats to verify they meet manufacturer specifications. Regular inspection of electrical components such as alternators, traction motors, and circuit breakers should be performed as part of the rebuilding process to maintain system integrity and prevent potential failures.

Cleaning andReconditioning Procedures

Once the critical component measurements have been documented, you’ll need to thoroughly clean and recondition all power assembly elements before rebuilding. Implement a systematic cleaning approach, starting with high-pressure washing of external surfaces to remove accumulated grime. For precision parts requiring deeper cleaning, utilize ultrasonic methods to eliminate contaminants without causing surface damage. Proper cleaning is essential to prevent water in cylinder issues that could lead to catastrophic engine damage if overlooked.

Apply chemical stripping with AAR/EMD-approved solvents to remove protective coatings and old lubricants from critical surfaces

Utilize wire brushing techniques on cylinder liners to address corrosion while maintaining surface integrity

Implement thermal cleaning in controlled environments for complex components requiring complete contamination removal

Perform post-cleaning inspection to verify all oil passages and cooling channels are completely debris-free

Your reconditioning techniques should match manufacturer specifications, ensuring each component meets dimensional tolerances before proceeding to reassembly. Remember to maintain vertical workspace organization throughout the cleaning process to prevent cross-contamination between cleaned and uncleaned parts.

Component ReplacementGuidelines

Proper component replacement represents the cornerstone of successful EMD locomotive power assembly rebuilding. When selecting replacement parts, you must adhere strictly to engine model-specific requirements. If you’re working with 567C engines, you can incorporate 645 power assemblies, but only after completing necessary upgrades to camshafts, injectors, and blower ratios. Never mix 567 and 645 assemblies within the same engine, as this compromises component compatibility and engine performance.

Pay particular attention to blade and fork rod pairings. These components share a common connecting-rod journal in V-type engines, with blade rods fitting inside fork rods in a “basket” arrangement that retains both components. This precise fit is critical for proper operation. Thorough inspection for internal failures using fiber optic endoscopes provides better evaluation of components before replacement.

For aftermarket considerations, select only parts meeting OEM specifications. Manufacturers like NRE offer both new and remanufactured power assemblies specifically designed for your engine model, ensuring reliability and compliance with industry standards.

Reassembly Sequenceand Torque Specifications

Successful EMD locomotive power assembly rebuilding depends heavily on following the correct reassembly sequence and adhering to manufacturer-specified torque values. Begin by preparing the block, confirming it’s clean and properly aligned for liner installation. Insert the liner with precise port alignment, then secure with crab nuts torqued to 200 ft-lbs in the recommended sequence.

Apply proper torque methods to critical fasteners: wrist pins require 200 ft-lbs with appropriate safety devices

Use ring compressors during piston insertion to prevent damage to rings and liner walls

Verify O-ring sealing in counterbores to prevent air box leakage and subsequent failure

Confirm correct blade/fork rod configuration to match the engine’s V-type design

When attaching the piston to the carrier, don’t forget the trust washer and snap ring installation. Pay special attention to proper alignment of the air holes along the cylinder liner to ensure optimal combustion air intake. These reassembly tips guarantee proper component integration, preventing premature wear and maintaining peak engine performance throughout its service life.

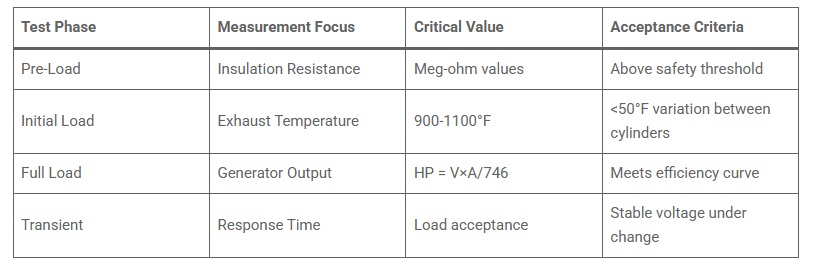

Testing andQuality Verification Methods

You’ll need to verify tolerances through precise clearance measurements to guarantee proper piston-to-liner fit and bearing surface integrity. For effective load testing, you must operate the power assembly under controlled conditions, monitoring oil pressure, temperature, and vibration according to ETS specifications. Verify performance by checking compression ratios and conducting blow-by tests, comparing results against the 95-second benchmark for acceptable sealing integrity.

Clearance MeasurementProtocols

When establishing proper tolerances between critical components in EMD locomotive power assemblies, meticulous clearance measurement becomes the foundation of reliable engine performance. You must understand the distinction between radial and diametric clearances, with radial being half the diametric measurement. Always select the appropriate measurement tools based on clearance types—feeler gauges for diametric measurements, dial indicators for longitudinal clearances, and micrometers for precise component sizing.

Calculate bearing clearances by subtracting shaft OD from bearing ID

Verify crankshaft alignment using dial indicators (maintain <0.003″ runout)

Use lead ribbon between components to measure precise contact clearances

Apply proper torque sequences (500-800 ft-lb) to guarantee accurate measurements

For main bearing bores, maintain specifications between 8.249″-8.252″ with out-of-round tolerances not exceeding 0.003″ when torqued to 650 ft-lb

Load TestingProcedures

With proper clearances established, load testing procedures represent the definitive validation of your rebuild quality. Apply APTA PR-E-RP-003-98 standards to adjust horsepower readings for ambient conditions and evaluate true performance.

Utilize resistive load boxes to simulate real-world conditions while monitoring critical parameters. You’ll need to maintain operating temperatures between 650-920°C during thermal evaluation cycles. Conduct both partial and full load tests to verify steady-state performance and transient response characteristics. This thorough load calibration guarantees your power assembly meets all performance evaluation criteria.

Frequently AskedQuestions

How OftenShould EMD Power Assemblies Be Rebuilt?

You should rebuild EMD power assemblies every 1,000,000 miles for 710-series engines or approximately every 7 years for locomotives operating under 100,000 miles annually. The 645E3 engine requires replacements every 20 years. Your maintenance schedule should account for operating conditions, with high-speed services needing more frequent rebuilds. Monitor rebuild frequency through regular inspections and adjust based on wear metrics like cylinder ring degradation.

Can DamagedLiners Be Reused if Properly Honed?

You can reuse damaged liners after proper honing, but only if they meet specific criteria. During liner inspection, verify that damage is limited to minor surface scoring without cracks or structural compromise. Honing techniques can address light wear by restoring crosshatch patterns and surface finish, but can’t repair deep scoring, cracks, or compromised gasket interfaces. Always verify post-honing dimensions remain within OEM specifications (±0.0005″ concentricity) and perform pressure testing afterward.

What CausesPremature Piston Ring Wear?

You’ll find premature piston ring wear stems primarily from inadequate lubrication quality. When oil levels drop or become contaminated with abrasives, the protective film between ring and cylinder wall breaks down. Thermal stress accelerates deterioration through expansion/contraction cycles that weaken piston ring materials. Poor combustion creates carbon deposits that interfere with ring movement, while improper break-in procedures can prevent rings from properly seating against cylinder walls.

Are AftermarketComponents Reliable for EMD Rebuilds?

You’re rolling the dice with aftermarket components for EMD rebuilds. While cost-attractive, aftermarket quality varies considerably between manufacturers. Component compatibility remains a critical concern—material properties and dimensional tolerances must precisely match OEM specifications. You’ll face increased reliability risks, potential certification complications, and compatibility challenges. For mission-critical applications, OEM parts provide superior reliability. If using aftermarket components, source from reputable suppliers with proven testing protocols and documented quality systems.

How DoEnvironmental Conditions Affect Rebuild Intervals?

Environmental conditions considerably impact your rebuild intervals. Extreme temperature fluctuations create thermal stress that accelerates component fatigue, particularly in power assemblies and cooling systems. High humidity levels promote corrosion on cylinder liners and metal surfaces, necessitating more frequent rebuilds. Operating in coastal areas with salt air or regions with severe weather conditions further degrades components. You’ll need to adjust your maintenance schedule by 15-30% when locomotives operate in harsh environmental zones.